Laminating is to cover a layer of color film on the metal plate. This is an innovation in the surface treatment of materials, which appeared in the late 1990s. This feature of the film is that it can keep for decades without fading and discoloration, with many colors, good senses, not easy to stain and easy to take care of. Japan and South Korea are among the countries that developed this new material early, and then introduced it to Taiwan and brought it into the country. At first, this technology was used in the decoration of the surface of electrical appliances, making the electrical appliances look more beautiful and high-end. In 2000, Taiwan Company, which was engaged in the development of keels and ceilings, transferred this technology to aluminum ceilings and achieved unprecedented success. As a kitchen and bathroom ceiling material, it has natural advantages: non-fading, non-shedding, non-deformation, non-sticky, easy to clean, stylish and beautiful, resistant to moisture, acid and alkali, and has a high cost performance.

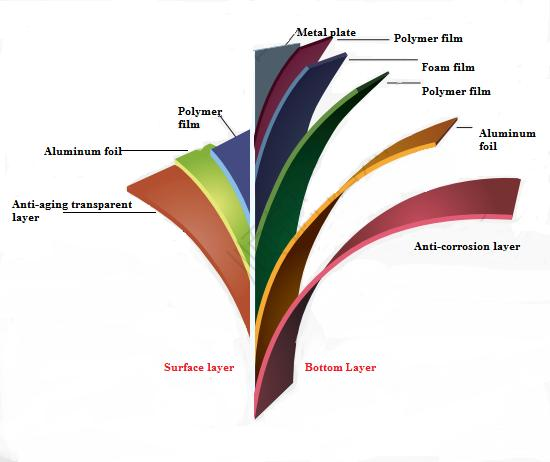

The process flow of the surface treatment of the laminated board is the same as that of the pre-coated board. It is made of PVC high-gloss film, PET film, and a special adhesive on the surface of the board. The thickness of the surface film is approximately 0.13mm (produced by general brands is .0.18mm thick film thickness). PVC high-gloss film has rich flexibility, gloss and color diversity, which completely changes the single cool color of the metal ceiling surface; PET magic film is currently the world's best new green environmental protection product, it has excellent durability ( Weather resistance, corrosion resistance, chemical resistance) and anti-fouling ability, non-toxic, pollution-free, anti-ultraviolet and many other superior properties, and are widely used, fully catering to people's longing for green, advocating environmental protection, and pursuing the concept of fashion.

Copyright © 2021 General Industry Tech Hebei Developing Co., Ltd. All Rights Reserved.